In the agricultural machinery maintenance sector, durability, structural strength, and stable performance are crucial. While storage equipment like custom toolboxes or tool carts may seem secondary, they directly impact operational efficiency and safety. Last year, Client H approached us for small-batch custom metal fabrication — five high-strength cabinets, each holding 100+ kg, with full design, prototyping, and delivery in just 90 days.

One-Stop Modular Design for Small-Batch Orders

Each cabinet differed in dimensions, load, drawers, and accessories. Using our one-stop metal fabrication approach, we standardized three heights, two depths, six drawer setups, and shared parts like locks, slides, and handles. This OEM-friendly modular system improved efficiency and sheet metal fabrication speed, while maintaining flexibility.

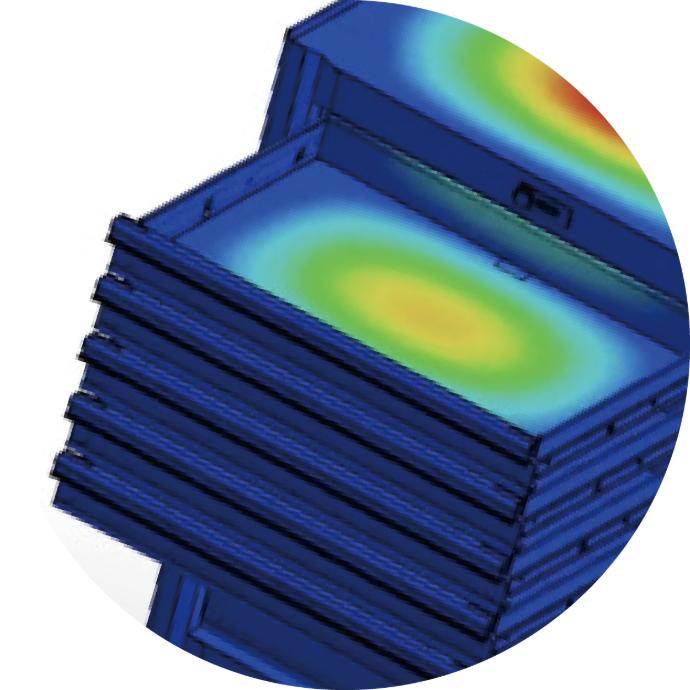

Precision Engineering with High-Strength Testing

We built frames from 1.0 mm cold-rolled steel reinforced with 2.0 mm plates, heavy-duty slides (60 kg per pair), and anti-sag supports. FEM tests confirmed over 20% more strength than required. This certified toolbox fabrication process impressed Client H’s European engineering team and was showcased at their trade exhibition.

On-Time Delivery in Just 85 Days

From sketch to shipment, we managed design, tooling, painting, assembly, and logistics within 85 days — ahead of the 90-day target. Our OEM metal fabrication services ensured on-time delivery to Germany, supporting their launch schedule without delay.

A Reliable OEM Partner

Client H’s German manager noted: “Not the cheapest, but the most reliable.” Our focus on high-quality results, stable lead times, and professional custom metal toolbox design makes us a trusted long-term partner in toolbox and tool cart fabrication.