Smart Manufacturing, Redefining Sheet Metal ODM Insdustry

AI-driven one-stop sheet metal OEM/ODM, from material cutting to final packaging, ensuring end-to-end efficiency, stability, superior quality, and faster lead times.

Coose Machan, Create Value-added product

Four Key Advantages Driving you ahead the market

Shortened Lead Times

Smart production processes ensure on-time delivery and strengthen supply chain stability.

Cost Saving

Optimized material usage and process efficiency increase productivity.

Consistent Quality

Strict process control and advanced technologies guarantee high-standard products.

Flexible solution

Capable of handling everything from small batch to large-scale production.

To Meet Diversified & Design Processing Needs,

Machan Introduces Industry-Leading Automation and Precision Equipment to Build an Efficient and Stable Production Process

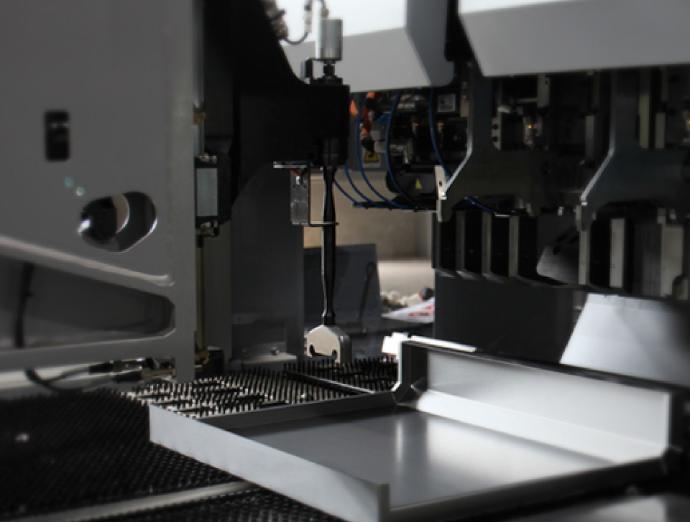

1. Salvagnini Automatic Bending Machine

Advantages:

Shortens production time to achieve efficient manufacturing.

Provides stable and consistent bending quality, reducing human errors.

Accommodates small-batch and diverse orders, offering flexibility to meet market demands.

2. Wagner and Gema Automatic Coating Equipment

Advantages:

Saves coating material costs and enhances environmental benefits.

Provides high-quality coating uniformity to meet durability and aesthetic requirements.

Applicable to a wide range of industrial product surface treatments, increasing market competitiveness.

3. UV Printing Machine

Advantages:

Offers high-resolution printing effects, enhancing product texture.

Supports customized designs to meet diverse market demands.

4. Automated Forming Machine

Advantages:

Reduces processing time and labor costs, boosting production efficiency.

Ensures high-precision forming quality to meet complex part requirements.

Supports both small-batch and large-scale production, flexibly adapting to market changes.

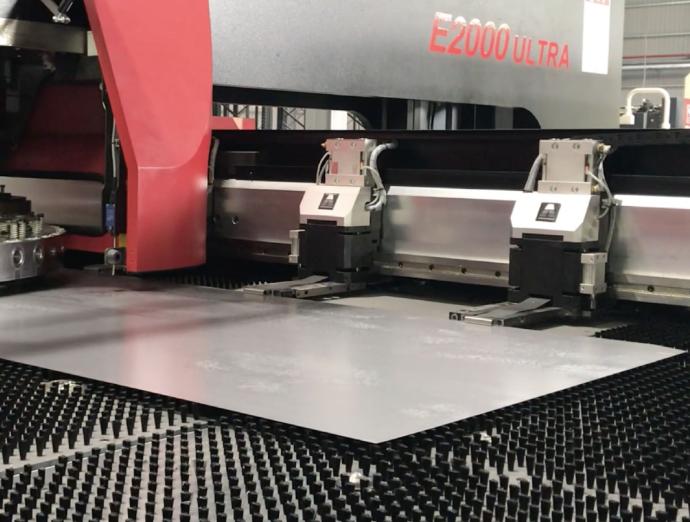

5. NCT CNC Automatic Punching Machine

Advantages:

Provides stable and consistent processing results, reducing defect rates.

Supports fast processing of complex workpieces, shortening lead times.

6. Laser Welding Machine

Advantages:

Delivers high-strength welding results, enhancing product durability.

Reduces thermal deformation, suitable for precision parts processing.

Shortens welding time, improving production efficiency.

7. PU Foaming Equipment

Advantages:

Reduces the use of polystyrene, aligning with environmental trends and decreasing reliance on non-recyclable materials.

Eliminates the need for stockpiling large quantities of packaging materials, saving storage and logistics costs.

Enables on-demand, on-site foaming based on product needs, improving packaging efficiency.

Recyclable and waste-reducing, supporting the circular economy concept.

8. Laser Cutting Machine

Advantages:

Enables rapid prototyping and verification.

Eliminates the need for mold-making, saving time and cost.

Well-suited for small-batch, diverse orders, offering flexibility to meet market demands.